1970 V10

Dodge Challenger

FEATURED IN

Popular Hot Rodding Magazine

Mopar Collector’s Guide

Featured in Mopar Collector’s Guide - March 2008

G-Force Challenger

By Randy Holden | Photos by Rob Wolf

Article from Popular Hot Rodding Magazine - January 2009

1970 Dodge Challenger - Big Noise From Shreveport

Matt Delaney's V10 Moparus Maximus Is A Bona Fide Ground-Breaker.

Ro McGonegal - writer; Robert McGaffin - photographer | Jan 31, 2009

In 1998, Time Machines (Hudson, Florida) built a ground-shaking purple Challenger. It looked like any other rendition from the outside, but under the hood, the TM crew had slung a Ram truck V10-actually rebuilt the front of the car to manage its new motivator. We believe it to be the premier conversion. But Matt Delaney's Charger rendition, built in 1999, was the first car to employ a Viper motor. So this idea isn't new, but is by far the most scienced-out V10 installation yet.

Delaney is no stranger to the pages of PHR. We've featured a couple of his outstanding creations already. So does this guy have a real job, or does he just fool around with vintage Hamtramck tin? Although he puts real estate and real estate developers together, we know that's really just a subterfuge for feeding his considerable and unquenchable Mopar lust, so much so that he builds them at his own Delaney Auto Designs (DAD) in Shreveport, Louisiana. His cohort and equal in this important occasion is Bill Reilly (up White Haven, Pennsylvania, way).

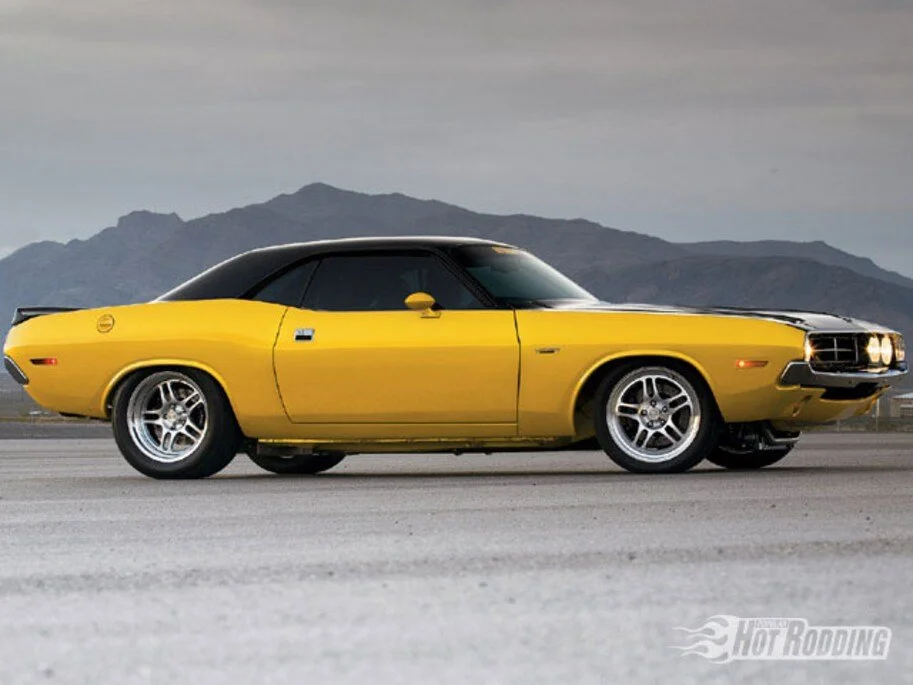

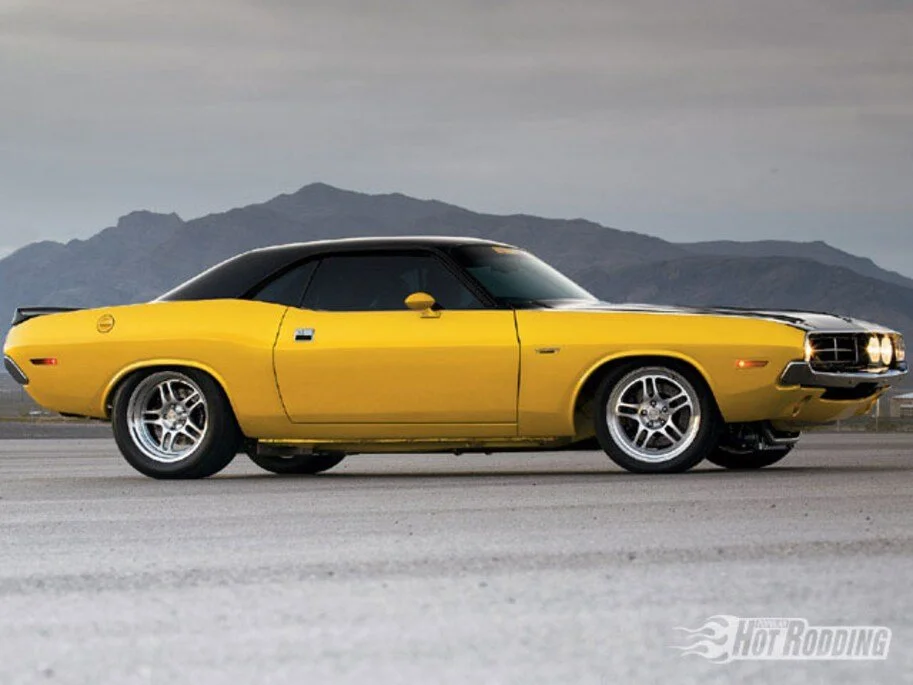

What appears to be just a warmed-over loved one is brimming with custom mechanical highlights, fabulous ideals and details. And Chevrolets, well, they can just go hang. With a substantial repertoire so far, Matt is regarded as a Mother Mopar standard bearer. His renditions are unique, thought-provoking, and bad-ass controversial. The Dodge folk understand his methods, too. This Challenger was on display in the Chrysler booth at the '07 SEMA show. Hard to miss it. Clean, neat, and looking just a little bit used (read: real).

Sure as hell, Matt drives this car just like all the others he's built. He made the run from Phoenix to Vegas for Mopars at the Strip in it, just one of countless sojourns he's made in his other children, a 526-inch '70 Road Runner, the '73 Red Dog blower-motor Duster, a Hemi-squeezed '70 AAR 'Cuda, the SRT8-powered '70 Challenger raggy, and so forth.

Other than something sticking ominously through the bonnet, Matt's Mopars are always faithful to the factory lines and flat hoods. Indeed, all the crazy stuff happens below the decks. This Challenger might be Delaney and Reilly's pinnacle automobile-so far, at least. In fact, to them it represents little more than a test bed mule. The intent was borne of the '68 Charger that Matt built in 1999. Aside from the Viper crate motor, it had a six-speed backed by a traditional four-link suspension. Through that experience, the pair identified areas of concern.

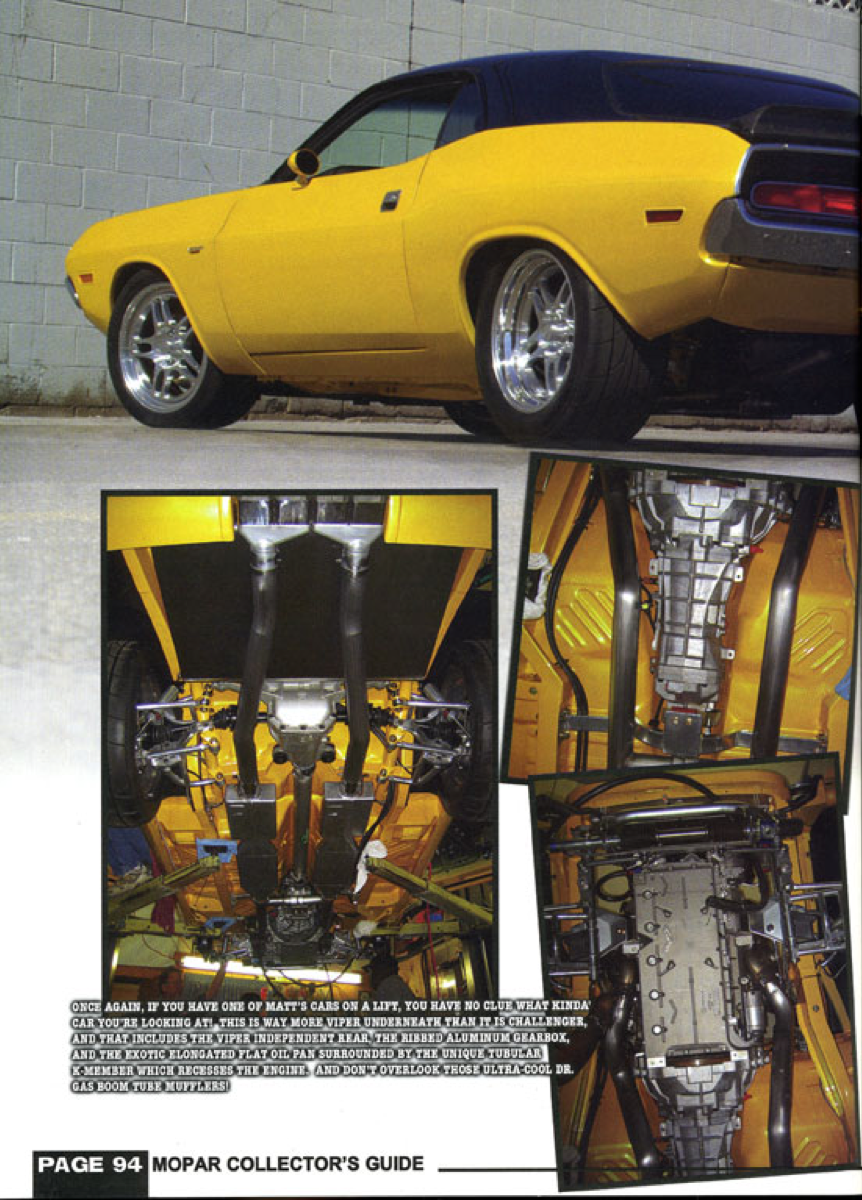

To accept the V10, the Challenger's firewall must be moved rearward 4 to 6 inches, something that no home wrench would feel comfortable with. The V10 maintains a long, flat-bottom sump that requires a higher-than-normal engine mounting location to clear the steering and suspension. In the Charger of old, the four-link worked great laying down straight lines, but was a detriment to precise, fluid handling characteristics.

Matt: "Although the requirements for this build sound common today-extreme performance and comfort, right at home on the street or track-the trick, however, was to pull it off using an out-of-the-box race-team Viper V10 (one of a handful), the brand-new T6060 six-speed, and HD Viper center section from Mopar Performance, and do it all with bolt-on parts and with as little cutting as possible."

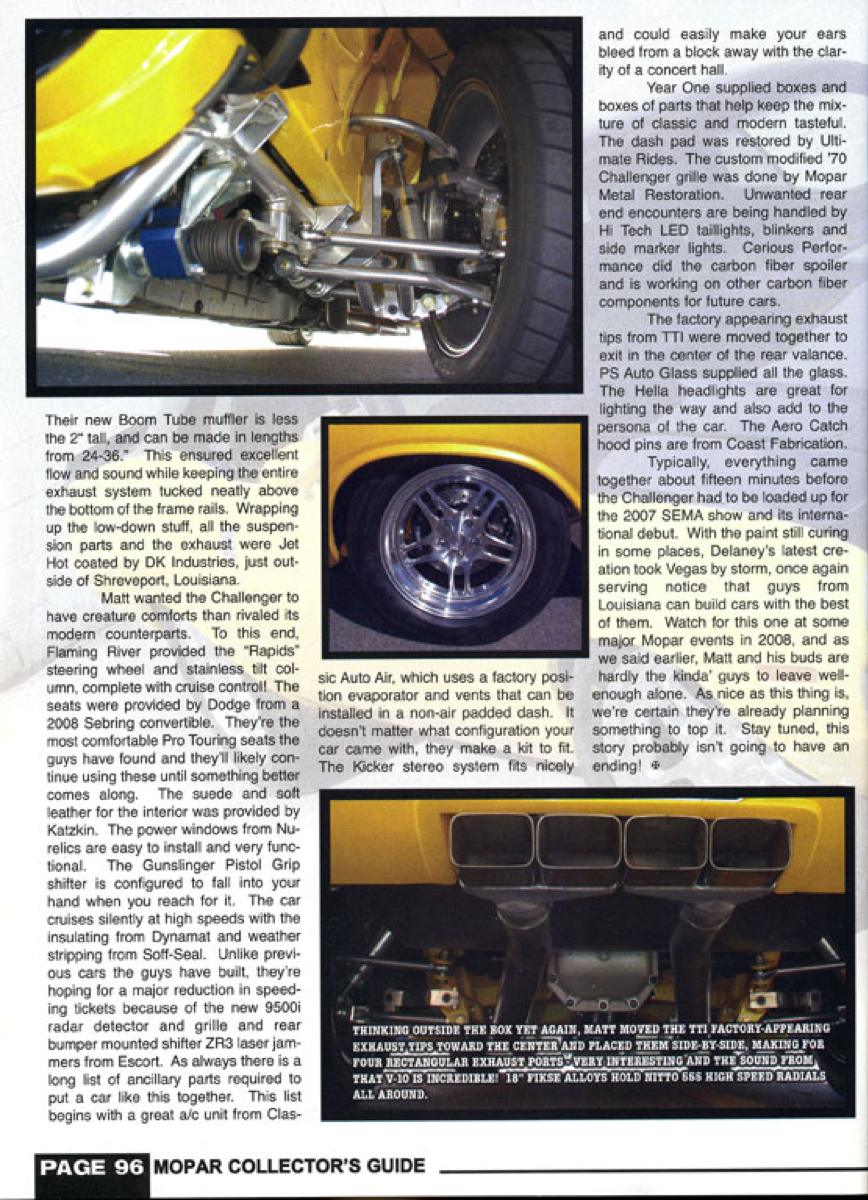

He favored the E-body this time because it has more undercarriage room than an A-body, and a shorter wheelbase than a B-body, so it can be a nimbler partner when esses and switchbacks start flying up. They originally contemplated the switch from torsion bar springs to conventional coils, but settled on the smoother ride afforded by the torsion bars, and fabbed a bolt-in K-frame that housed the adjustable splined bars internally, thereby increasing clearance for the suspension. To counter the V10's fat and abundant torque, DAD installed braces where there were none before: from firewall to shock tower, from left framerail to right framerail underneath the radiator, subframes tied together, and a new brace beneath the rear seat.

In turn, these modifications relinquished quite enough clearance to narrow the width of the track substantially so that the 285/35 tires (on 9-inch wheels) don't bump into the fenders or framerails. To situate the motor in the desired location ahead of the stock firewall, they developed a rear-steer, center-steer power rack ahead of the engine, and behind the radiator cowl, and an adjustable Z-bar steering linkage that correctly places the tie rods and reverses the travel direction of the rack.

This construction corrected a number of geometry issues and allowed a full Ackerman ratio in a very tight turning radius. Lock-to-lock is 1.8 turns. Now that's tight, bro. The payoff, though, was watching the V10 slip into place ahead of the firewall and about 5 inches lower in the engine bay than previously possible. The result is a very favorable center of gravity for a bent-road athlete. To complete the puzzle, DAD incorporated a smaller-than-stock billet aluminum thermostat housing, a high-flow Wizard Cooling aluminum core, and four SPAL electric fans. As standard procedure, they cleaved the driveshaft tunnel to give the big T6060 breathing room. Enthusiasts rejoice. Matt hints that this conversion could soon become a Direct Connection retrofit.

The 10-cylinder lathe sends 610 lb-ft of grunt to the Direct Connection coconut. DAD's custom cradle holds it as attached to its own subframe, a prototype of yet another retro-fit kit, Matt winks. To keep everything well matched, he hid the torsion bar design to keep them out of the way and to accommodate the 305/45 fatties in the stock wheelwells.

Prior to these shenanigans, Matt had the shell acid-dunked at Metal Rehab (Dallas, Texas), and then added the needed Goodmark Industries sheetmetal. He also specified framerail connectors and rear factory torque boxes from Harms Auto. The floor of the trunk is actually the top of the custom fuel cell. In addition to the braces at the front of the car, he included five additional stringers in the undercarriage as well.

Matt's close association with Dodge availed him a handbuilt engine. He talked them out of a Team Viper 2006 spec race motor, a 488-incher that produces 610 lb-ft at 3,600 rpm and 585 hp at 6,200 rpm, more than enough moxie to send the 3,400-pound Challenger into orbit by simply tapping the loud pedal and producing a cacophony that would be hard to ignore all the way down in Lake Charles.

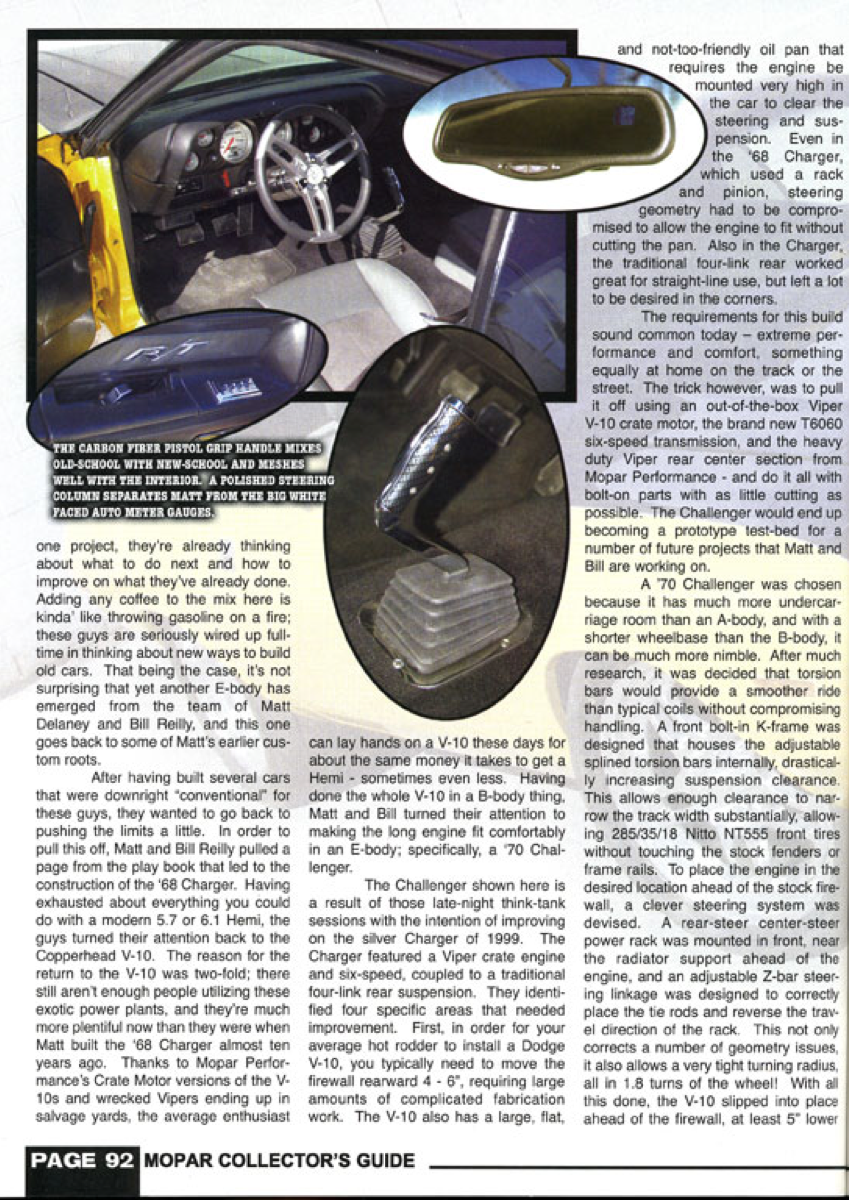

Delaney Auto decided that the car should have nothing less than the most modern comfort and convenience schedule, hence a Flaming River tilt steering, Nu-relics power window lifts, Dynamat deadener, Soff Seal weather stripping, Classic Auto Air HVAC, and an audio army capable of letting blood.

A gorgeous animal by any motorhead's estimation. All you remember here is engine, engine, engine. The relocated V10 uses stock tubular headers as well as the factory heat shields.

By The Numbers: '70 Dodge Challenger

Matt Delaney - Shreveport, LA

Vehicle weight w/driver: 3,600 pounds

DRIVETRAIN

Transmission:Tremec Viper T6060, Dodge twin-disc clutch, Gunslinger Pistol Grip on stock shifter

Driveshaft:The Driveshaft Shop steel, 4340 1350-series yokes

Rear axle:2008 Viper third member, clutch-type differential, 3.06:1 ring-and-pinion

CHASSIS

Front suspension:Delaney Auto Design K-member and spindles, custom torsion bars, QA1 adjustable shock absorbers, custom anti-sway bar

Rear suspension:2008 HD Viper center section, The Driveshaft Shop custom-length half-shafts, DAD hand-built subframe, hidden torsion bars, QA1 adjustable shock absorbers

Brakes:Hydroboost booster, Wilwood tandem master cylinder, Finelines stainless lines, 6-piston, 13-inch Superlite, front; 4-piston, 12.9-inch Dynalite, rear

Wheels:forged Fikse Profil 5S 18x9, front; 18x10, rear

Tires:Nitto 555 285/35ZR, front; Nitto 555R 305/45ZR, rear

ENGINE

Type:Dodge V10 displacing 505 cubic inches (4.03 bore x 3.96 stroke)

Block:2006 Gen-3 Viper spec race engine (proprietary)

Compression ratio:10.6:1

Oiling:stock, 7-quart aluminum, swinging pick-up

Rotating assembly:stock Viper 3.96-inch stroke forged crank, forged rods, and pistons

Cylinder heads:stock Viper, 2.005 intake/1.585 exhaust valves, 1.7:1 rocker arms

Camshaft:factory hydraulic roller, .550-inch lift, 245-deg. duration at .050

Induction:Mopar SEFI, 34lb/hr injectors, Volant cold air intake, 23-gallon fuel cell, -10 braided lines, submersed Aeromotive pump, Aeromotive fuel regulator.

Power adder:none

Ignition:factory

Exhaust:factory tubular manifolds, Dr. Gas mufflers, Jet-Hot coated 3-inch exhaust system, TTI exhaust tips

Fasteners:factory spec

Built by:Viper Race Group